Products

Wire springs

Various model of springs

Compression springs (φ0.15~8.0)

Extension/torsion springs(φ0.4~4.0)

Compression, extension and torsion springs (Designed from calculated specifications)

Compression springs (φ0.15~8.0)

Extension/torsion springs(φ0.4~4.0)

Compression, extension and torsion springs (Designed from calculated specifications)

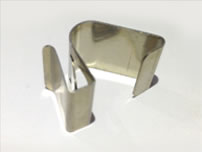

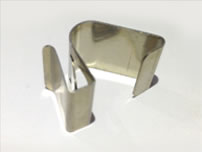

Flat springs

Flat springs (extra light flat springs), material quality SUS/SK etc

Stainless steel, special steel for springs 0.2t~ (Flat springs, plate springs, wave washer etc)

Design and manufacturing considering the spring back

Stainless steel, special steel for springs 0.2t~ (Flat springs, plate springs, wave washer etc)

Design and manufacturing considering the spring back

Stamped parts

Sheet thickness (t=0.2(SK5)~6.0(SPH440))

◆2.0mm thick narrow groove processed with t4.3mm SPHC material

Thanks to our unique processing technology, we can remove groove capillarities up to half the board thickness.

We can process with various equipment from 30t one-shot press to 200t transfer press.

◆2.0mm thick narrow groove processed with t4.3mm SPHC material

Thanks to our unique processing technology, we can remove groove capillarities up to half the board thickness.

We can process with various equipment from 30t one-shot press to 200t transfer press.

Shearing

◆Parts accuracy

① Whole circumference shearing by one-shot molding (Shearing lenght:70% of the board thickness/surface roughness:Ra3.2).

② Partial shearing by transfer molding (Shearing lenght:80% of the board thickness/surface roughness:Ra1.6).

Thanks to the improvement of our molding process technology, we can shear with standard press machine.

① Whole circumference shearing by one-shot molding (Shearing lenght:70% of the board thickness/surface roughness:Ra3.2).

② Partial shearing by transfer molding (Shearing lenght:80% of the board thickness/surface roughness:Ra1.6).

Thanks to the improvement of our molding process technology, we can shear with standard press machine.

Wire-forming

SWM-B(Φ4.5~Φ10) /Piano wire(Φ4.5~Φ8.0)

Product lenght:up to 1200mm

We can straighten coil material though roller correction equipment and process using programable controllers.

We also have no loss of material when creating coil material.

Product lenght:up to 1200mm

We can straighten coil material though roller correction equipment and process using programable controllers.

We also have no loss of material when creating coil material.

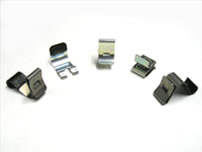

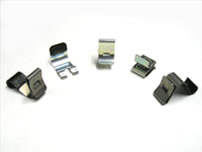

Multi-forming

SPCC(MAXt1.5) /material width:MAX50mm

Thanks to facilities equiped with both press and bending machinery, and servo-motors controlled arms, we are able to continously process complex bent products.

Thanks to facilities equiped with both press and bending machinery, and servo-motors controlled arms, we are able to continously process complex bent products.

Chemical polishing

◆Installation capacity:Board thickness (T=0.9~10)/product diameter (Φ8~Φ135)

◆Part accuracy:Parallelism (0.02MIN)/board thickness(±0.02MIN)/surface roughness(Ra0.2MIN)

Because we can polish both sides at the same time, it is easy to respect the board thickness/parallelism and suppress any heat treatment strain.

◆Part accuracy:Parallelism (0.02MIN)/board thickness(±0.02MIN)/surface roughness(Ra0.2MIN)

Because we can polish both sides at the same time, it is easy to respect the board thickness/parallelism and suppress any heat treatment strain.

Sub-assembly

We can realise riveting, spot welding and all sort of assembly.